Landini REX4 Electra – Evolving Hybrid receives EIMA Technical Innovation Award 2020-21

The prestigious Eima International Technical Innovation Award has gone to Landini again.

After winning with their Advanced Driving System in 2018, the Argo Tractors group is once again honoured with the award thanks to the Electra – Evolving Hybrid system, also intended for the Landini REX4, which is to take centre stage both at Eima Digital, the preview scheduled on a web platform from 11 to 15 November, and at the physical edition of Eima 2021, scheduled from 3 to 7 February at the Bologna Fiere fair district.

“For Argo Tractors this is an important recognition that rewards our great commitment to, and our investment in research and development, which enable us to achieve cutting-edge technology levels for our tractors” – commented a satisfied Giovanni Esposito, Innovation Director at Argo Tractors on hearing the news about the award. “The evolution of our products provides customers with the most innovative solutions to optimise productivity and improve the quality of their work, with great focus – as ever – on the human factor. From this point of view, the Electra system – Evolving Hybrid – has been designed to further enhance the handling, comfort and ease of use of REX4 tractors, so as to meet the needs of a contemporary customer base – using new technology to guarantee cost-effectiveness with an eye to the environment and sustainability, which are always primary objectives”.

Intended for orchards and vineyards, Landini REX4 has already gained a reputation for its handling prowess and ease of use, which combine with astoundingly thrifty running costs to meet the needs of the most demanding customers.

Such qualities are coupled with solutions that also look to increase the efficiency of the tractor system and further improve comfort during the long hours spent driving the tractor.

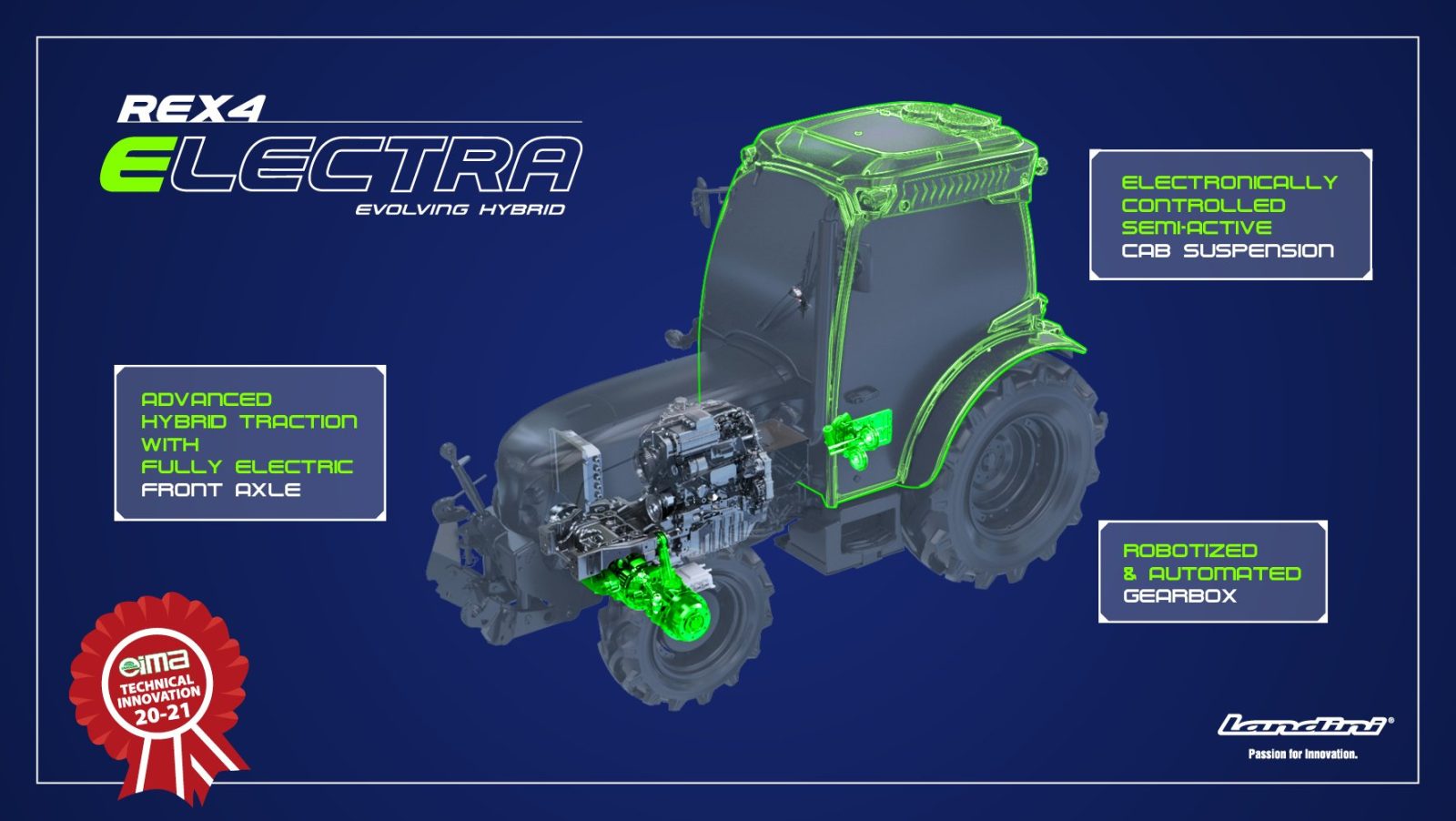

Landini REX4 Electra – Evolving Hybrid features an innovative electric front wheel drive with independent wheels, brake energy recovery, a cabin with electronically controlled semi-active suspension and a semi-automatic transmission that lets you select speed using a joystick.

Of this original project Argo Tractors has developed both the mechanical part and the electrical components. REX4 Electra is equipped with a 110 hp Diesel engine, Reverse Power Shuttle transmission and 3 Powershift speeds (H-M-L).

The most significant new features include a fully electric front wheel drive with suspended axle, sporting two independent electric motors and associated sensors, electronic controls, generator and battery dedicated to energy recovery under braking and deceleration.

The entire system is controlled by the PMS (Power Management System), which supervises the operation of all devices, including the battery and controls motor and generator via their respective inverters.

This modern approach made it possible to create a hybrid tractor in which the Diesel engine powers the front electric motors through generator and battery, and continuously “talks” with the conventional mechanical rear final drives. The result is basically a parallel hybrid with a system that is independent of the mechanical ratio between the rear and front wheels of the tractor.

This combination of technological improvements guarantees 10% fuel savings, a 15% wider steering angle and greater stability in transport mode, fully integrating with the current electric steering system.

A new electronically controlled cab suspension is also included to increase comfort, thanks to a semi-active system similar to that already available on high-end tractors. Suspended on four points, the cab is equipped with two passive front suspension systems, while two anti-damping hydraulic shock absorbers governed by an electric signal reduce vibration at the rear. A control unit detects tractor movement and rough ground and regulates damping in real time and continuously. Again, the system can be fairly described as hybrid, a balanced compromise between a “soft” behaviour to take up vibration and a “stiffer” setup to prevent the cab from hitting the travel stops.

The improvement in comfort can be clearly appreciated both in the field and on the road, with a 15% less vibration transmitted to the driver.

A semi-automatic transmission uses actuators to operate the transmission rods. A multifunction joystick in the cab replaces the traditional speed lever. The electronic control unit (ECU) receives a change-speed input from the joystick and the data about tractor status from the sensors. When the conditions required for changing speed are met, the ECU signals the actuators to move the transmission control to the desired position. The advantages are obvious: fully automated shifting, one less mechanical lever in the cab (drive by wire), resulting in less noise and pollutants.

REX4 Electra – Evolving Hybrid – is yet more evidence of how passionately Landini continues to work on renewing agricultural mechanisation, and remains an undisputed leader in the sector worldwide.